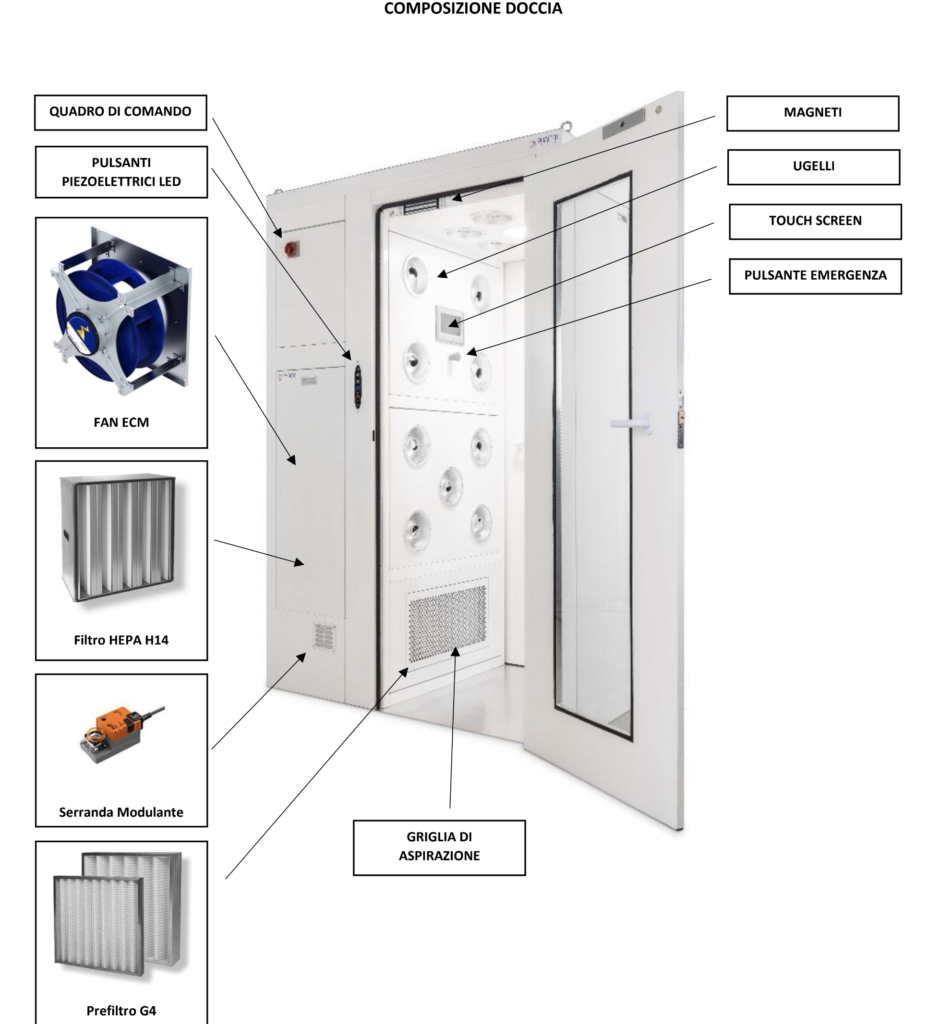

A prerogative of controlled contamination environments is the control and management of contaminants. Contaminants must not be spread inside, or outside in the case of harmful dust, of the controlled areas. A very effective method is to equip such environments with special machines, called ‘air showers’, that can remove any fibres or dust deposited on the clothing of personnel entering or leaving two environments. This removal is done by means of air showers. Each air shower consists of high-pressure nozzles evenly distributed over the shower’s inner surface. A high-capacity air stream, pre-filtered by HEPA filters, is able, through contact with the garment, to detach particles from the operator. The contaminated air is taken back into the base of the shower by special grilles so that it can be filtered again and put back into circulation.